Introduction

For designers of isolated systems, rapid advances in digital isolation technology are yielding new capabilities that greatly simplify their job. Examples include integrated, isolated power and truly bidirectional isolation channels that can reduce system costs and save circuit-board real estate. These advances are fueled by a shift away from LED-based optocouplers toward newer isolator technologies that are compatible with standard foundry CMOS processes. They enable integrated circuitry to be packaged with chip-scale mICrotransformers, thus fitting more functionality into a single package.

This article discusses two kinds of devices that embody these advances. In the first example, isolated power, chip-scale microtransformers are complemented by switches, rectifiers, and regulators to produce an isolated, regulated dc-to-dc converter; when integrated with isolated data channels it provides a complete isolation solution. In the second example, bidirectional isolation, integrating the requisite buffers and drivers creates an isolator that has truly bidirectional isolation channels without the need for external signal conditioning.

Isolated Power: isoPower

Galvanic isolation is employed to transmit data and/or power across a safety barrier, while also blocking charge or current flow across that barrier. The Analog Devices iCoupler® family of digital isolators uses chip-scale microtransformers to provide cost-effective, space-efficient isolation. iCoupler technology was introduced in “iCoupler Digital Isolators Protect RS-232, RS-485, and CAN Buses in Industrial, Instrumentation, and Computer Applications” (Analog Dialogue 39-10, October 2005).

Figure 1 shows a 4-channel digital isolator, which houses three dice in a single package. Two CMOS interface circuits (left and right) integrate drive and receive electronics. The middle die contains four chip-scale microtransformers, each comprising metal (AlCu and Au) coils on either side of a 20‑μm polyimide insulation layer. The polyimide is capable of withstanding more than 5 kV rms for one minute.

Unfortunately, in most applications that require isolated data transmission, isolated power must be available on both sides of the isolation barrier, or it must be provided separately. System designers typically introduce isolated power by designing an isolated power supply using discrete components—including a transformer with the appropriate isolation rating—or by purchasing a commercial off-the-shelf isolated dc-to-dc converter.

Each approach has its advantages and disadvantages. In the first instance, isolated power supplies may be custom tailored to an application, allowing system designers to optimize their cost, isolation rating, power output, or other important specifications depending on the application requirements. The downside, however, is that custom solutions tend to be bulky, require safety certification, and can lengthen development times.

Commercially available isolated power supplies, on the other hand, can reduce time to market, but they carry a price penalty and may not be optimized to fit a particular application. While smaller in size than their custom counterparts, they are still fairly bulky, with only limited availability of surface-mount package options.

A third way is isoPower, which combines the benefits of both options. iCoupler digital isolators condition and drive data across the transformers as described in the article, “High Speed Digital Isolators Using Microscale On-Chip Transformers.” isoPower uses the same chip-scale microtransformer technology, but instead of transmitting only data, isoPower employs switches, rectifiers, and regulators to generate power that is isolated to the same degree as the data channels.

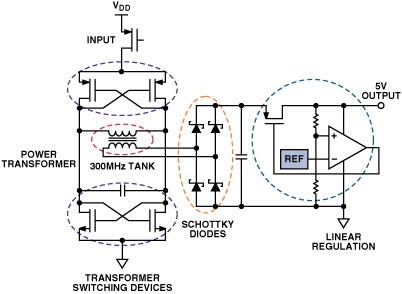

Figure 2 shows the isolated power section of the ADuM5240, ADuM5241, and ADuM5242, the first iCoupler products with isoPower. Four cross-coupled CMOS switches generate an ac waveform that drives the transformer. On the isolated side, Schottky diodes rectify the ac signal. The rectified signal is passed to a linear regulator, which maintains the output voltage at a nominal 5-V setpoint. Efficiency can be significantly improved by giving up one of the isolation channels to provide feedback across the isolation barrier to the transformer switches.

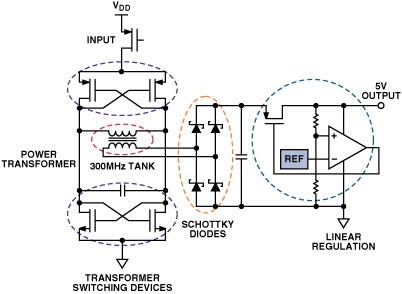

Figure 3 depicts the transformers used in the ADuM524x family. The chip-scale microtransformers are made from 6-µm thick gold, separated by a 20-µm polyimide insulation layer, which is capable of providing greater than 5-kV rms isolation. Because the transformer coils, only 600 μm in diameter, have a low L/R ratio compared with conventional transformers, high-efficiency power generation requires high-frequency switching—on the order of 300 MHz.

As noted earlier, the transformers used to generate power employ the same process as those used to isolate data. The only significant difference between data and power channels is the conditioning circuitry on either side of the isolation barrier.

isoPower Example

Combining data and power in a single, small, surface-mountable package, the ADuM524x family provides significant size and cost savings. Figure 4 shows typical physical configurations for isolated SPI interfaces. The iCoupler-and-isoPower solution (Figure 4a) uses an ADuM5240 and an ADuM1201 to provide four channels of isolated data and up to 50 mW of isolated power, enough to power an ADC and a remote sensor. It is more compact and less expensive than the traditional approach using three optocouplers and an isolated dc-to-dc converter (Figure 4b). A third solution, using discrete transformers and other components, would consume even more area. Other combinations of ADuM524x isoPower and ADuM120x iCoupler products are possible, as are combinations of ADuM524x and most other iCoupler products.

The small size and low cost of an isoPower solution opens up new possibilities for the placement and distribution of isolated sensors and reduces the cost of existing solutions, thereby enabling wider adoption of isolated sensors.

A case in point is turbidity sensors: they measure the amount of particulates in a liquid solution and can be used to determine the cleanliness of a volume of water. They are increasingly being used in home appliances, such as dishwashers and washing machines, both to conserve water and to improve cleaning performance. Conventional appliances wash or rinse for a set time, overestimating the required level of cleaning to ensure that the load is fully clean at the end of the cycle. A turbidity sensor, however, can let the system know when to stop cleaning. The machine will use the optimal amount of water for the optimal time, thus minimizing waste while maximizing useful cleaning performance.

Because turbidity sensors must be immersed in the water, they present two challenges to an appliance designer. First, the sensor must be small enough to fit unobtrusively anywhere within the space where clothes or dishes are to be placed. The size of the sensor is, therefore, critical. Second, the powered circuit is immersed in water, so the sensor must be safely isolated from the rest of the system. If the physical insulation should fail, the user and the system electronics must not be harmed, and there must be no possibility of fire. Both the power and the data must therefore be isolated.

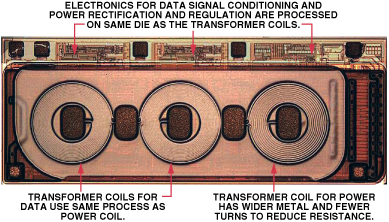

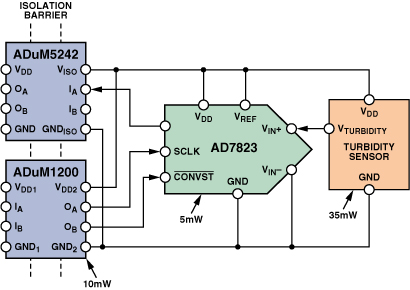

The block diagram shown in Figure 5 demonstrates a cost-effective solution. The AD7823 low-power ADC uses a 3-wire interface to convert the analog output of a turbidity sensor. The digitized turbidity data is transmitted across the galvanic isolation barrier of the ADuM1200 and ADuM5242. The 50 mW of isolated power from the ADuM5242 is sufficient to supply the ADuM1200, the AD7823, and the turbidity sensor. The combined area of the isolators and converter is less than 100 mm2, excluding external components.

Bidirectional Isolation

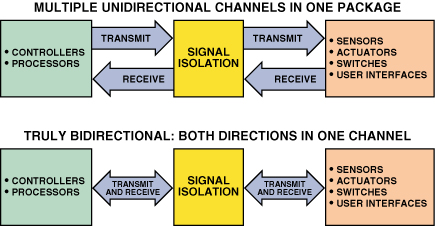

In isolation, the term bidirectional has traditionally referred to an isolator with separate transmit and receive channels in one package—the isolator as a whole is capable of bidirectional data transfer, but the individual channels are unidirectional. This approach is compatible with communications protocols such as RS-232, RS-485, and SPI, but it is not compatible with true bidirectional communication protocols, such as I2C®, SMBus, and PMBus, which support bidirectional data transfer through a single channel. Bidirectional and unidirectional isolation are compared in Figure 6.

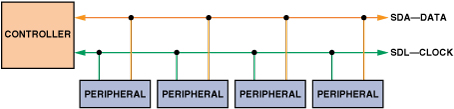

The inter-integrated-circuit (I2C) bus is a popular 2-wire, bidirectional communication protocol that was developed to provide simple, low-cost, short-distance communication between an on-board controller and its peripherals. I2C buses limit the cost of applications in which multiple devices share a single bus with a host controller, as shown in Figure 7. Two bidirectional wires—one for the data and one for the clock—are used to achieve low cost at the expense of data rate, so I2C is typically used in systems with many peripherals running at data rates less than 1 Mbps. Systems that use a limited number of peripherals running at higher data rates will often employ protocols such as SPI.

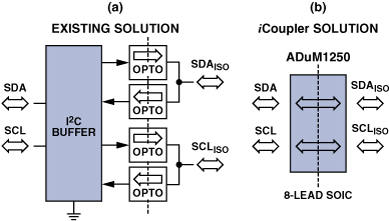

The I2C isolation challenge has been that optocouplers are based on diodes that can transmit in only one direction, and are therefore inherently unidirectional. A bidirectional I2C bus could be isolated using optocouplers, but the implementation isn’t pretty (Figure 8a). A special buffer is used to separate each bidirectional channel into two distinct channels: transmit and receive. once separated, the four unidirectional channels can be individually isolated and then recombined. This solution requires four isolators and expands the bus from two wires to four wires. Additional circuitry is also required, making this solution costly and large, and defeating the original purpose of the 2-wire bus implementation: to save money and space.

The good news is that by adopting the new digital isolation techniques the circuitry that is used to separate, isolate, and recombine the data channels can be integrated into a single package. This approach can be implemented with the new ADuM1250 and ADuM1251 hot-swappable dual I2C isolators. Figure 8b illustrates how much more compact the iCoupler solution is.

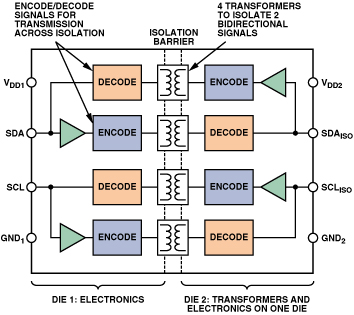

Figure 9 shows how bidirectional isolation is achieved within the package. Just as the discrete solution employs a buffer to separate the two bidirectional channels into four unidirectional channels and four isolators, so, too, does the ADuM125x. The difference is that all the electronics are integrated onto a single IC. A designer sees only the 2-wire interface, and the entire device is less than 40 mm2, a 90% reduction compared with the optocoupler/buffer solution, which takes up about 350 mm2.

Future Isolation Solutions

As these examples illustrate, digital isolation continues to offer simplified and novel solutions to challenging design problems. This is achieved at low cost through the use of standard foundry processes that enable integration of features not typically found in classical isolation solutions. In the near future, we can expect to see further advances, with isoPower being integrated into an increasing number of isolation applications; and we can also expect to see other novel solutions for isolating buses that are more complex than I2C.

客服微信

客服微信 查ic网订阅号

查ic网订阅号